Warehouses that burst at the seams with overstock use copious resources to keep the lights on and products temperature-controlled. Sustainable warehousing should become the standard, and energy management is a critical fixture of greener operations. It is one of the few factors impacting everything within a building, including budgets, carbon footprints and employee health. Effective management practices will reduce the growing impact of commercial infrastructure and bring warehouses into a climate-friendly age.

Understanding Energy Consumption in Warehousing

Commercial buildings, including warehouses, are responsible for 17.2% of the nation’s energy use, primary consumption and system energy losses. This statistic demonstrates a massive opportunity for drastic climate improvements. As utility professionals know, the places causing the most energetic waste include:

-

Lighting

-

HVAC systems

-

Refrigeration

-

Equipment and technology operation

-

Transportation

-

Additional indoor environmental control

Most warehouses run 24/7, meaning they remain operational during peak demand periods. Even one hour extra will divert essential resources from the public grid, leading to imbalances in availability and high costs for the warehouse.

Operators and electricity professionals are responsible for identifying the most prominent sources of wasted energy, besides utilities. Red flags could include poor insulation or outdated equipment pulling more power than it should. Retrofitting and replacing these weak points is essential for reducing energy costs in warehouses.

Energy Management Practices

Eco-friendly warehouse design begins by discovering how to transition to a green warehouse model. These are the best actions and intelligent energy management assets your facility can adopt.

Energy Audits and Monitoring

Conducting regular audits or outsourcing this task to an expert optimizes warehouse energy use for sustainability and cost savings. Technicians who know what saps the most resources can prioritize efficient installations based on their impact. Routine assessments are also a prerequisite for reaching environmental compliance goals, such as LEED certification. These often require buildings to cut consumption and monitor power.

Additionally, professionals may suggest adopting an energy management system to track data in real time. A top-consuming organization in Vietnam incorporated an EMS and saved 191,923 kilowatt-hours within the first six months, reducing carbon dioxide emissions by 139 tons.

Upgrading Lighting Systems

Lighting massive warehouses to provide visibility consumes massive amounts of power. Case studies where companies have achieved LEED compliance show how much optimizations can cut lighting demands.

One of the world’s best-known brands decreased its facility’s lighting power density by 71% after multiple improvement attempts. Warehouses may achieve this through LED lighting, smart controls and using natural light.

Optimizing HVAC Systems

HVACs rank among the top three commercial systems that demand the most capital resources, especially because they never last the entire building’s life span. However, employees can lengthen their equipment’s usefulness for sustainability and energy efficiency.

Regular maintenance is critical, such as replacing filters and inspecting for performance detractors like rust and buildup. When warehouses replace equipment, they should focus on certified eco-friendly, energy-conscious options.

To supplement these machines’ performance, installers can put sensors and smart thermostats nearby to respond to heating and cooling needs more intelligently. These work in tandem to assess occupancy and outdoor temperatures, then automatically adjust as needed with less waste.

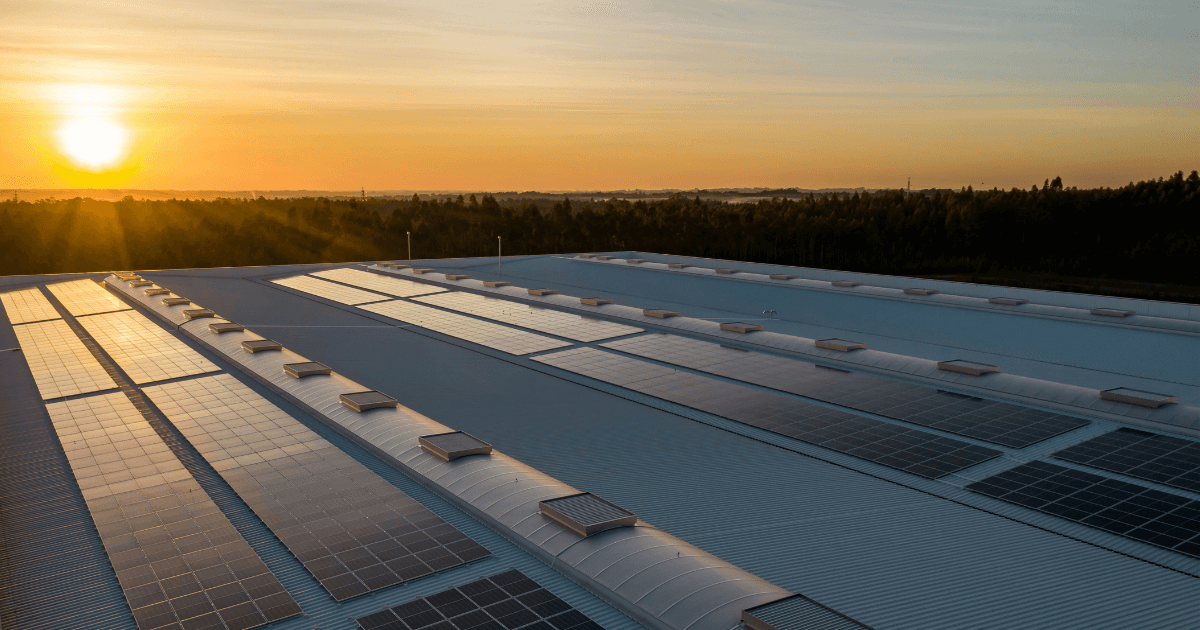

Implementing Renewable Energy Solutions

Switching to carbon-friendly generators is the best way to make warehouses more sustainable in energy management. Technologies like solar panels on massive warehouse roofs are straightforward ways to gather the company’s needs with free and clean methods. Enterprises can also look into geothermal, hydroelectric and wind, though these are location-dependent. Many warehouses may want multiple on-site technologies to diversify their energy management portfolio, making them more resilient to intermittency and climate stressors.

Renewable infrastructure includes more than solar panels, wind turbines or heat pumps. It may also include external battery energy storage solutions or attachments to microgrids. These benefit the community in addition to the warehouse because they store additional energy to use during peak hours and allow neighborhoods to access the grid.

Intelligent Technology Use in Energy Management

Technologies like robotics, the Internet of Things, artificial intelligence, automation and software maximize the value of a minute in a warehouse. Some may not even need light or heat to function. Tasks run on autopilot, alleviating burdens on workers to undertake more complex assignments. Implementations like warehouse racking and storage systems and telemetry have these benefits, which cut energy consumption and costs:

- Reduced working hours and overtime

- Lower utility costs

- Potential to get power from renewable resources

- Increased efficiency to reduce energy waste

Programs like digital twins and building information modeling are also critical for finding causes of high energy use. These can simulate building changes like switching to a different lighting or HVAC system, allowing teams to achieve a 92% success rate in their design optimization goals.

Many of these electronics provide lifelong benefits for warehouses because they collect data. Use analytics to embrace a continuous learning mindset, continuing to visualize ways to become energy efficient.

Employee Training and Engagement

Education is the driving force behind a warehouse that successfully develops energy awareness in the long term. Employees must feel motivated to help the building cut waste. They should also learn to use the tools correctly, as misuse can lead to unintentional overconsumption.

Warehouses must institute thorough, regular training programs that encourage workers to learn new ways to improve with the many data-gathering technologies at their fingertips. There will always be insights to share with your staff.

Technicians who are interested in energy management techniques are more likely to increase efficiency in operations. Warehouse stakeholders boost the chances of this happening by establishing a new culture of sustainability.

Sustainable Warehousing Strategies for Reducing Your Carbon Footprint

Operators must take actionable steps to implement green warehouse solutions. Energy oversight will enhance additional eco-friendly goals, including waste reduction and water conservation, because these processes are also energy vampires. Starting with an energy-efficient mindset will optimize your warehouse’s financial savings and impact reduction.