What is Renewable Natural Gas?

For years, renewable natural gas (RNG) has primarily been used to maximize financial and energy performance in the agribusiness and waste management sectors. RNG is compositionally identical to fossil natural gas, with the only difference being the isotope makeup of the carbon. It can come from a variety of organic sources (like biomass digesters, landfills, and wastewater treatment plants) or it can be chemically produced. In the US, there are more than 200 RNG production facilities, with most associated with biomass digesters or wastewater treatment plants.

RNG is primarily used for transportation (e.g., compressed natural gas-powered garbage trucks), with a small amount being used to make renewable electricity. An advantage of RNG production is that it gives value to what would otherwise be waste material, whether that be manure, food waste, or sewage. It also reduces methane emissions from landfills and wastewater treatment plants.

Financial Incentives

The catch to RNG is it’s about 50% more expensive to produce than traditional fossil natural gas. However, some of that cost can be offset by financial incentives.

RNG is often assigned a renewable identification number (RIN), a unique serial number for every unit of renewable fuel. The RIN system is part of the EPA’s Renewable Fuel Standard enacted in 2005, with RINs tradeable to parties like oil refineries which need to show a percentage of fuels being produced using renewable sources. A RIN unit is defined by the Environmental Protection Agency (EPA) as 77,000 BTU. RNG has a heating value of approximately 1,037 BTU/SCF, meaning every cubic foot of RNG is worth 0.013 RINs.

RINs from RNG fall into the D3 or D5 categories, depending on the feedstock. RNG from cellulosic feedstocks produce D3 RIN numbers and RNG produced from food waste, fats, sugars, or starched produce D5 RIN numbers. The values of D3 and D5 RIN numbers are around $2.50 and $1.50, respectively.

Several states offer credits to produce RNG. These credits are designed to incentivize RNG production to help it compete with conventional natural gas. The exact credit amount varies by state, but is usually in the form of a tax credit or a monetary credit that can be sold on the market. Credits are typically based on the amount of RNG produced, with some states also considering the source of the RNG (e.g. whether it’s from a landfill, manure digester, etc.).

California awards low carbon fuel standard (LCFS) credits to RNG producers if the RNG replaces fossil transportation within state boundaries. In addition, RNG doesn’t have to be produced in California to take advantage of the credit. RNG projects must register with the California Air Resources Board (CARB) LCFS tracking system. RNG injected into a natural gas pipeline must maintain a chain of custody verification from a CARB accredited third party.

Producing RNG

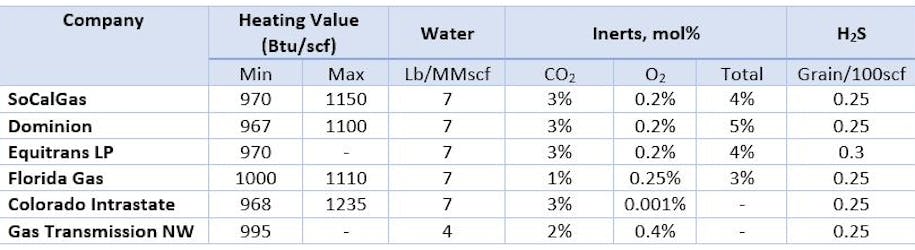

There are multiple methods available for producing RNG. Here, we’ll go into them in deeper detail. One important takeaway is that if the RNG is going to be transported offsite via a utility pipeline, it will need to meet the pipeline operator’s quality requirements. Example pipeline quality standards are shown below in Table 1:

Table 1: Gas quality standards for some pipeline operators in the United States.

In addition to cleanup, the RNG needs to be compressed to between 500 and 1,400 psi to match pipeline pressures. A chain-of-custody metering skid is needed to quantify the amount of natural gas transferred.

Method #1: Biomass and Landfill Gas

Most RNG currently produced is a comes from biomass digesters, landfill gas, and wastewater treatment plants.

Bacteria anaerobically decompose organic matter, producing a biogas rich in methane with some impurities like CO2 and water and trace amounts of H2S, NH3, N2, and alcohols. To make RNG, biogas needs to be conditioned to remove these impurities which otherwise make the biogas difficult to transport or store or could cause problems in internal combustion engines.

There are several processes for conditioning biogas into RNG. Often, more than one of these processes is used in series:

- Membranes

- Water Scrubbing

- Pressure Swing Adsorption

- Solid Scavenging Media

Landfill gas requires additional steps for stubborn impurities like siloxanes and dimethyl sulfide.

Method #2: Biomass Pyrolysis

Emerging processes for RNG production involving chemical processing can greatly increase the amount of RNG available.

Biomass pyrolysis involves heating a feedstock in an atmosphere devoid of oxygen to temperatures ranging from 320-800°C. Steam or catalysts help the pyrolysis reactions along. Biomass pyrolysis produces a gas rich in methane with some higher-order hydrocarbons, hydrogen, water, alcohols, and tars. Purifying pyrolysis gas into RNG requires a series of steps:

- Tar reforming and filtration

- Water scrubbing for HCl and NH3

- Sulfur removal

- Compression

- Water gas shift

- CO2 removal with solvents or membranes

- Dewatering

- LPG recovery

Because of the complexity and capital costs associated with pyrolysis-based RNG, these systems are more expensive than biogas systems. However, pyrolysis systems can handle a wider range of feedstocks. Essentially, anything with carbon-carbon and carbon-hydrogen bonds is a suitable feedstock. This not only includes biomass, but municipal waste and plastic. A technical challenge for biomass pyrolysis is the tar byproduct which fouls piping and causes other process disruptions.

Method #3: Sabatier Reaction

Another way of making RNG is through the Sabatier reaction. This reaction converts hydrogen and CO2 into methane and trace amounts of higher-order hydrocarbons while generating a considerable amount of heat. The Sabatier reaction has already been demonstrated on the International Space Station and there are plans for using it to generate rocket fuel on Mars. The CO2 for the process can come from other processes (e.g., carbon capture) or purified from the air.

For methane made via the Sabatier reaction to be truly considered RNG, the hydrogen source needs to be green. One way of doing this is the electrolysis of water using green electricity.

Another method, the syngas route, solves the demands for both CO2 and hydrogen. Syngas is mostly hydrogen and carbon monoxide (CO) and can be made from a variety of feedstocks, including biomass and municipal waste. After some initial cleanup to remove tars and particulates, the syngas undergoes sulfur removal before passing through water-gas shift reactors. The water-gas shift reactors convert CO and water to CO2 and additional hydrogen. CO2 is removed using either solvents, membranes, or pressure swing adsorption to maintain a CO2/H2 ratio of 1:4.

The combined stream then heads to the methanation reactor, making methane, water, and a considerable amount of heat. The co-generated heat can be used to produce steam and electricity. Water is separated from the methane and any other impurities are removed before it’s pressurized and introduced to the pipeline as RNG.

Like pyrolysis, RNG from gasification and the Sabatier reaction can handle a variety of feedstocks but process complexity adds significant cost. Also, like pyrolysis, tars produced during biomass gasification require special consideration.

Conclusion

RNG offers ways to turn waste products into fuel and we’re already doing it. New methods are offering ways to scale up RNG production will make a substantial impact in our energy mix.

Article originally published on the POWER Engineers website.