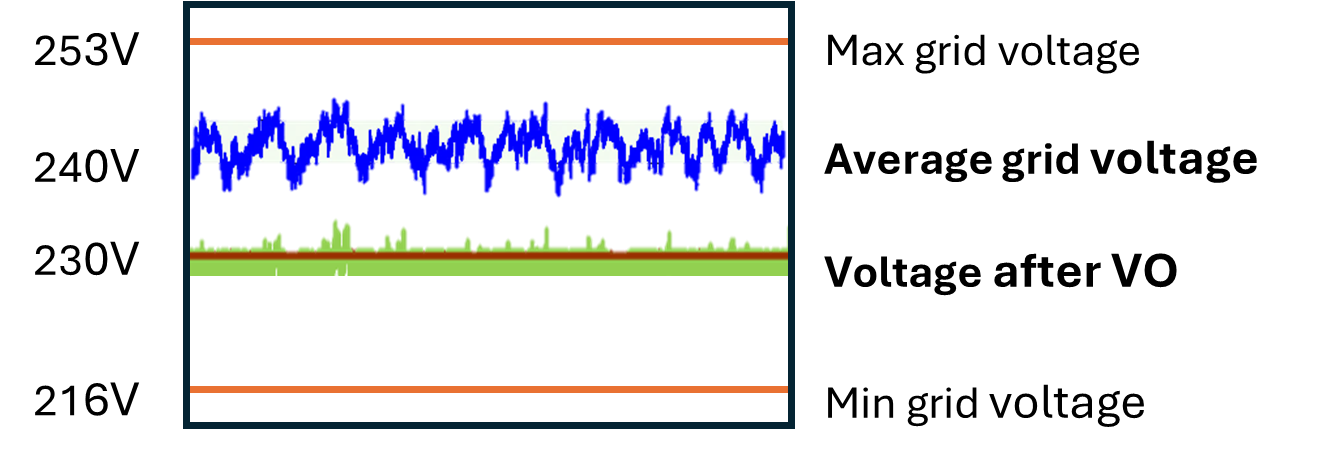

The grid electricity supplying your facilities and processes is intended to ensure minimum voltage everywhere on the network, but not necessarily to supply your loads with the smooth, optimum voltage they are designed to operate at. The grid supply is often characterised by excess voltage, variation and spikiness.

Using this voltage to supply your electrical machines is inefficient and causes excess wear and financial costs.

Voltage optimisation (VO) solves that problem by switching the grid supply to the most efficient voltage, and by also smoothing out fluctuations (see Figure) it can reduce electricity consumption and wear on your electrical assets.

Quality VO installations have a range of risk mitigation mechanisms in place, including surge protection, inline fuses and undervoltage protection. This ensures that VO delivers the most cost-effective energy usage across a site without any increased risk of disruption. Real-time monitoring and reporting ensure that those savings are completely transparent, helping users to make further informed decisions on their energy management.

How does it work?

A traditional VO will act like a transformer stepping a primary voltage down to a desired secondary voltage but this method of switching voltages can be inefficient. Alternatively, a modern, efficient VO may use a third winding between the primary and secondary that transforms a subtractive power, achieving the desired voltage with significantly reduced losses, this third winding can also be switched off to allow savings tests to be conducted.

The benefits of reduced voltages are realised in inductive loads such as motors, as excess voltages increase magnetizing losses. Similarly, motors supplied with a lower voltage than nominal also see significant losses, as increased resistive losses are introduced.

Benefits of Voltage Optimisation

Installing voltage optimisation equipment maintains site supply close to a nominal single-phase of 230V. This delivers tangible energy reductions across an entire site with the installation of a single piece of equipment. Alongside a reduction in daily operating costs, this also delivers a reduction in CO2 emissions and can extend the lifespan of most electrical equipment.

When it comes to the return on investment for voltage optimisation, the energy cost savings unlocked by optimised site voltage and better energy efficiency are only part of the equation. Optimised voltages also substantially reduce wear and tear on electrical equipment and infrastructure, which in turn can dramatically reduce repair and replacement costs, as well as reducing incidents of costly downtime due to equipment failures. For sites with large amounts of sensitive equipment and high incoming voltages, these savings can quickly add up and contribute significantly to the overall cost savings VO can offer.

The conditioning of incoming voltage also improves a site’s power resilience in another way. As sites become increasingly electrified and incorporate more smart technologies, even minor voltage spikes or sags can cause sensitive equipment to trip or shut down. These brief disruptions can lead to lengthy restart processes, resulting in significant productivity losses. Additionally, the increased digitisation of sites heightens the risk of sudden shutdowns, which can result in the loss or corruption of vital data.

Will VO save money and carbon for my organisation?

A quick estimation of potential savings can be made with half-hourly data and a recent bill. If the initial analysis is promising, a non-intrusive on-site voltage logging survey can be conducted to confirm the energy consumption reduction.

A bottom-line electricity consumption reduction of between 5 and 10% is expected, but savings are commonly in the region of 7, 8 or 9%.

Payback periods will vary depending on electricity consumption and profile and your kWh price. Under 3 years is the target and under 2 years is often achieved. Where payback periods extend beyond 3 years it is worth noting that a well-designed, installed and maintained VO saves electricity and carbon from day 1, and can keep saving money for decades.

VO can be installed into existing electrical architecture in a weekend and is compact enough to fit inside existing switch rooms. In installations where it needs to be located outside, suitable weatherproof housings can be supplied.

Is VO appropriate for my site?

As part of a cost reduction or sustainability strategy, VO is being used to save money and carbon in all areas of manufacturing, retail, services, and the public sector.

If electricity is a significant cost for your site, it is worth consulting a VO specialist to see what savings you could make.

Robert Greenacre (Business Development Manager) – Powerstar (Sheffield UK)