Combustion Fuel nozzles are a vital component of a gas turbine engine. Many owners and operators realize the importance of paying close attention to fuel nozzle maintenance specifically the tight flow tolerance of a complete set of fuel nozzles in gas turbine engine performance. Owners and Operators who fail to understand the impact fuel nozzle maintenance have on the rest of the system often experience an increase in overall costs and a decrease in total performance. Improperly maintained fuel nozzles, not properly balanced (flowed), can also have adverse effects on the life of the HGP components and major components such as the rotor, buckets, blades, and vanes. In addition to the increase in outage costs, the potential of lost revenue resulting from the extended outage or de-rating the unit may also occur.

Key Takeaways

1. Improved start-up and tuning of turbine after overhaul

2. Reduced temperature spreads that lead to flashback/lean blowouts and derating of the turbine

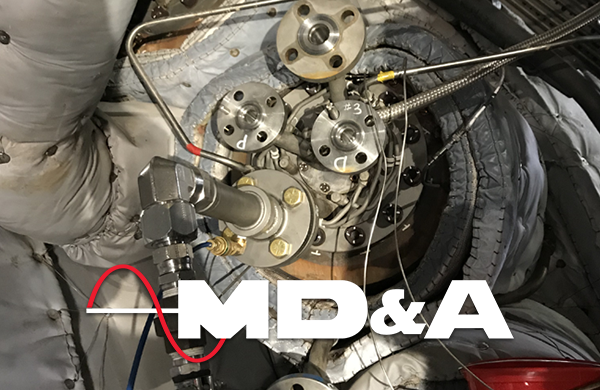

3. Customers identify or eliminate potential fuel nozzle issues as part of their overall turbine operating issues using in situ portable test stand