MD&A performed inspection, replacement, and repairs for various GE® steam turbine control components for a US-based customer. The extensive and varied list included valves, actuators, spring cans, hydrogen seals, and many others.

Work was divided among MD&A’s teams including the Bearings, Seals & Hydraulics (BSH) team and the Valves Team of MD&A Machining Services Division and conducted as follows:

Valves

MD&A’s Valve Team performed inspection, replacement, and repair on various valves and related components. These included control, main stop, reheat stop and intercept valves, as well as a blowdown and a ventilator valve. Each valve was disassembled, blast cleaned, dimensionally checked and repaired as required. All valve work was completed at MD&A’s Turbine-Generator Repair Facility in St. Louis, Missouri.

Control Valves – All four control valves failed the incoming inner valve blue check which was corrected by lapping the pilot valve seats. The team honed the bushings on valves #1 and #2 to correct stem to bushing clearance issues. They also replaced several components as needed, including the disc and balance chamber, anti-rotation screws, stems, bushings and pins. Disc to balance chamber clearance issues and out of tolerance run outs were noted on valves #3 and #4. Clearance was restored by hand working the blue blush from the balance chamber IDs and grinding the disc ODs. Several other clearance issues were found and resolved by honing, grinding, or lapping. MD&A supported vendor performed NDE, revealing indications on two valves, which were excavated and hand blended by the team.

Reheat Stop Valves – New stem nut pins were installed on both valves during reassembly. Further, the stems were machined, and backseats were lapped to achieve acceptable blue checks. The valve disc seating surfaces were ground and polished as well. MD&A’s valve technicians also replaced the stem, inner/outer bushings and back seat on the R/S valve.

Intercept Valves – The two intercept valves were found to have similar issues among them. Both had several clearance deficiencies, which were remedied by grinding, honing, or machining. Component replacements included the crosshead guide busing, as well as disc bolts on both valves. The stem on the L/S valve was machined, drilled, and pinned; while the R/S valve had the backseat machined and lapped to achieve acceptable blue checks.

Ventilator Valve – This valve required the stem OD to be lapped. To ensure proper contact, the main disc seating was ground and polished. MD&A’s Valve team replaced the air cylinder gasket, the balance chamber, and corrected the valve lift during reassembly.

Blowdown Valve – Our technicians reset the gap between the piston stem and valve stem and restored the inner valve lift. They also polished the pilot valve and lapped the valve seat in the main disc. The main disc seating surface was ground and polished. Replacements included the air cylinder gasket and piston rings, air cylinder fitting and the bushing.

Main Stop Valves – For both valves, the team cut the stem back seat and lapped the pressure seal head backseats to achieve a good blue check. They ground and polished the disc contact seating surfaces, skim cut the gasket faces and restored the disc cap peening lips. Further, on the R/S, the bypass valve and disc seat were skim cut, and the stem was replaced. On the L/S, various clearances were restored as required.

Compression Rings

MD&A’s experts inspected and repaired two compression rings. Damage including corrosion was observed and remedied on both rings. The rings were oxide blast cleaned to bare metal. The I.D. and O.D. of the lower face were then weld repaired. The rings were then machined.

|

|

|

EHC Actuators & Spring Cans

MD&A’s Bearings, Seals & Hydraulics (BSH) team disassembled, inspected, repaired, and tested ten GE® EHC actuators and spring cans. The coil springs were shot peened, mag particle inspected, and painted. The spring cans had several components replaced including seals, bushings, and bearings. The cans were bead blasted and painted. The team tested the actuators to confirm they were functioning properly and leak-free prior to leaving our BSH repair facility.

|

|

|

Additional Components

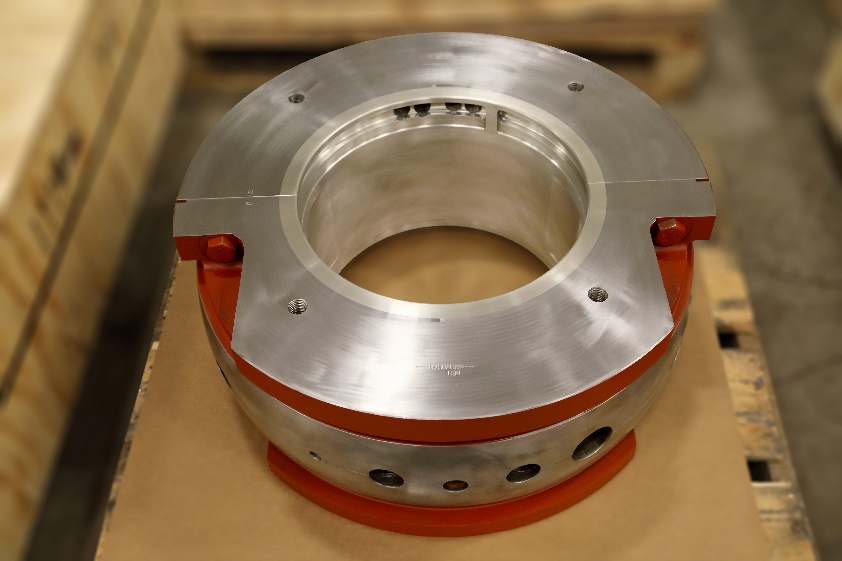

The BSH team also inspected and repaired several additional components including the overspeed trip, two tilt pad bearings, eight journal bearings, eleven oil deflectors, four hydrogen seal bronze assemblies, and two hydrogen seal housings.

Overspeed Trip was disassembled, cleaned, and inspected. Several components were replaced including the spindle, upper and lower bushings, eccentric ring, and lock plates. Weld repairs were performed on the body, spring seat, and spring shim. Trip speed was set and the unit was test.

Tilt Pad Bearings were in acceptable condition. Babbitt pads were cast and bored. New seal teeth were installed and also bored. One bearing required boring on several anti-rotation pin holes.

Journal Bearings underwent centrifugal cast repair. The inspection revealed that several dowels were no longer acceptable, and were replaced. Bearing T8’s body bolts were also not acceptable, and re-fit.

Oil Deflectors – all units received new teeth. One deflector required modification to accommodate insert-style teeth. Several required new body bolts.

Hydrogen Seal Bronze Components were machined to be within manufacturer’s specifications. As for the housings, the dowels were replaced on one unit, while the other required bolt replacement.

|

|

|

Conclusion

The extensive range of work and complexity involved in this project highlights one of MD&A’s greatest strengths: being a dependable one-stop solution for virtually any power-generation repair need. The scope demanded the expertise of two teams of experienced engineers and technicians, who performed quickly and properly, to the customer’s satisfaction. As the go-to service provider for power generation asset owners across the globe, call MD&A today at +1 (518) 399-3616.

Also be sure to sign up for our MD&A Insight e-newsletter delivered quarterly. Fill in sign up form and SUBSCRIBE!