The media covers most of the headwinds that are hindering our climate change goals: Interconnection, supply chain, siting and permitting procedures… But there’s one that receives little coverage. Perhaps because it involves a mature and mundane technology: transformers.

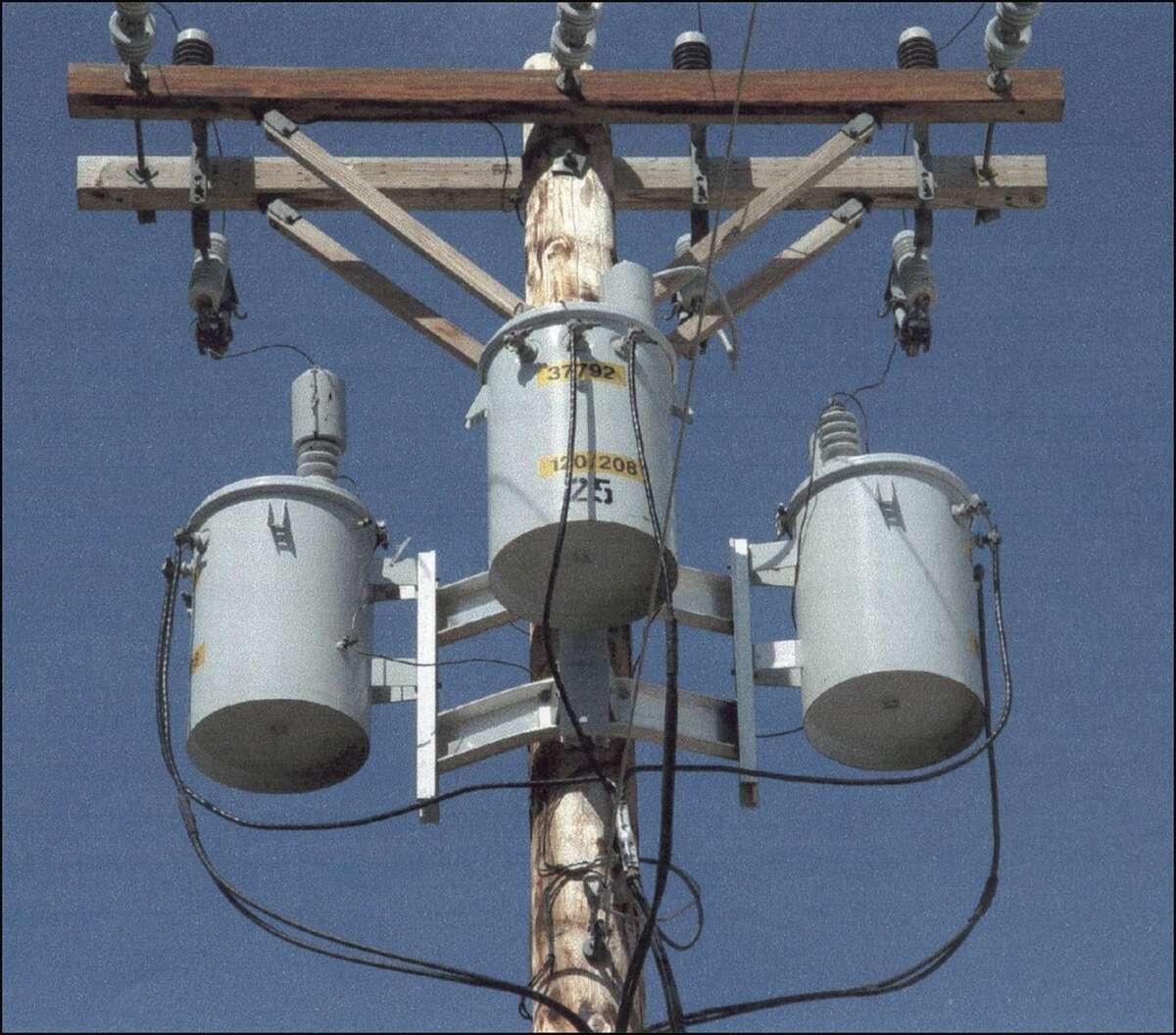

We’ve all seen them even if we didn’t know it. There are basically two categories of transformers: large power transformers located at substations, and distribution transformers – which are the cylindrical devices hiding in plain sight on many utility poles. These essential grid components convert voltage and enable power to be sent to homes and businesses. But the only time we hear about transformers is when one blows out and causes a blackout.

We currently import about 80% of our transformers. Lead time for power transformers can stretch out to 18 to 24 months. More problematic is that the Department of Energy has warned that most large power transformers will need to be replaced soon. The average age is around 40 years while the normal life expectancy is only 20.

The situation with distribution transformers is not much better. With demand outstripping supply, prices have spiked and delivery times have been stretched from what was once three months to 12 to 18 months.

But there is a silver lining: the issue has united Democrats and Republicans. Last month a bipartisan group of senators introduced legislation that they claim will address the shortage of distribution transformers. The legislation would stop the Department of Energy from enacting rules to improve efficiency standards but potentially compound the delivery problem by requiring transformer manufacturers to use a different kind of steel.

The Distribution Transformer Efficiency & Supply Chain Reliability Act of 2024 would still address efficiency levels but kick the can 10 years down the road. Note that efficiency standards for distribution transformers haven’t been updated since 2013. Barring the passage of this legislation, the proposed DOE standard would become effective in 2027 and it estimated to save consumers roughly $15 billion over 30 years.

At the heart of the problem is that there is only one domestic supplier for the new type of steel: Tempel – owned by Worthington Steel. Then again, there is only one domestic manufacturer for the currently used steel: Cleveland Cliffs. Still, this type of transition is likely to cause some supply disruptions which could increase our dependent on imported steel which comes with a 25% tariff.

Any way you look at it this, it’s far from ideal. We’ll keep an eye on things to see if they improve or deteriorate further.

#powertransformers #powergrid #clevelandcliffs #tempel #worthingtonsteel #utilitytransformers